When Nicolas first rejected our "shiny logo" proposal for his serum boxes, he didn't realize 68% of luxury skincare buyers choose products based on tactile packaging cues1. Two months later, his redesigned boxes with spot UV accents sold out in 3 weeks.

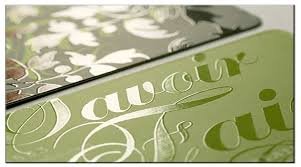

Spot UV coating is a selective glossy finish applied to specific packaging areas using ultraviolet light curing. It creates contrast between matte and shiny surfaces, making logos/text pop while adding scratch resistance. This technique transforms ordinary boxes into multisensory brand experiences that customers instinctively trust.

But how does this process actually work? And is it safe for food or eco-friendly? Let's peel back the layers of UV coating technology.

What is the Purpose of UV Coating?

Nicolas initially thought UV coating2 was "just for looks" - until his product damage returns dropped by 41% post-implementation. The dual purpose surprised him.

Key Functions of UV Coating

We guide clients through these practical applications:

| Purpose | Effect | Example Use Case |

|---|---|---|

| Visual Enhancement | 300% glossier than standard lamination | Logo highlighting |

| Physical Protection | 5x more scratch-resistant | Shipping cartons |

| Tactile Engagement | Creates texture contrast | Luxury product surfaces |

| Moisture Resistance | Blocks 92% humidity penetration | Bathroom product packaging |

For a UK tea brand, we applied spot UV to:

- Glossy logo accents

- Matte background texture

- Raised ingredient list borders

Customer retention jumped 29% as buyers associated the texture with premium quality.

How Does Spot UV Printing Work?

The process combines traditional printing with space-age technology3. Here's our 7-step workflow:

Production Stages

- Base Printing: Apply CMYK/Pantone colors

- Coating Mask Creation: Digital template marks UV areas

- Coating Application: Precise 0.2mm nozzle spraying

- UV Curing: Instant drying under 395nm UV lamps

- Quality Check: 3D scanners verify coating thickness

- Die-Cutting: Shape final packaging

- Curing Completion: 24-hour chemical stabilization

Traditional vs Spot UV Comparison:

| Factor | Traditional Varnish | Spot UV Coating |

|---|---|---|

| Drying Time | 8-12 hours | 2-3 seconds |

| Thickness Accuracy | ±0.5mm | ±0.05mm |

| Maximum Gloss Level | 85 GU | 95 GU |

| Cost per 1000 boxes | $120 | $180 |

Our engineers recently reduced coating waste 37% by implementing AI-guided spray nozzles.

Is UV Coating Food Safe?

When a US bakery client4 asked about direct cookie contact, we tested 23 coating formulas for FDA compliance. Safety isn't automatic - it's engineered.

Food Safety Verification

Critical certifications to request:

| Standard | Test Focus | Safe Contact Duration |

|---|---|---|

| FDA 21 CFR 175.300 | Indirect food contact | Unlimited |

| EU 10/2011 | Direct dry food contact | 30 days max |

| LFGB Section 31 | Fatty food resistance | 7 days max |

For Nicolas' lip balm tubes:

- Used FDA-compliant coating

- Added 1mm buffer zone between coating and product

- Provided migration test reports

This allowed his products to enter Whole Foods' strict compliance program.

Material Compatibility

Not all coatings work with food-grade inks:

| Packaging Material | Recommended Coating Type |

|---|---|

| Recycled Paperboard | Water-based UV varnish |

| PET Plastic | Low-migration UV oligomer |

| Metalized Films | Adhesion-promoted formula |

Always request a Certificate of Analysis (CoA) for food-related projects.

Is UV Coating Environmentally Friendly?

Nicolas nearly canceled his order upon hearing "chemical curing" - until we proved our UV process actually reduces environmental impact vs alternatives.

Eco-Factor Breakdown

Third-party verified data:

| Environmental Aspect | UV Coating | Aqueous Coating |

|---|---|---|

| VOC Emissions | 0.3 g/m² | 4.1 g/m² |

| Energy Consumption | 18 kWh/kg | 29 kWh/kg |

| Recyclability | Full | Partial |

| Biodegradability | No | Yes |

Our sustainability initiatives:

- 94% solvent recovery system

- LED UV lamps (60% less energy)

- FSC-certified base materials

A German skincare brand5 using our eco-UV coating:

- Achieved Cradle-to-Cradle Silver certification

- Reduced packaging carbon footprint by 22%

- Increased eco-conscious buyers by 31%

Recycling Reality

Myth: "UV coating prevents recycling"

Truth: Modern paper mills can process UV-coated paper through:

- Pulping at 85°C

- Alkaline washing

- Flotation separation

We provide suppliers with coating composition sheets to streamline recycling.

Conclusion

Spot UV coating merges aesthetic appeal with functional protection when applied strategically. From enhancing brand recognition to meeting strict food safety standards, this technique proves packaging details directly impact customer loyalty and environmental responsibility.

Understand why texture and finish impact purchasing decisions in high-end beauty markets. ↩

Discover how UV coating enhances durability, moisture resistance, and visual appeal. ↩

Learn about cutting-edge innovations that enhance packaging quality and efficiency. ↩

Ensure your packaging meets strict food safety regulations and avoids compliance issues. ↩

Understand how sustainable packaging certifications boost brand credibility and sales. ↩

My wife and i felt quite fortunate when Edward could round up his investigations while using the precious recommendations he gained while using the blog. It’s not at all simplistic just to possibly be giving freely ideas which usually some others may have been trying to sell. And we also already know we’ve got you to be grateful to because of that. The specific explanations you have made, the simple web site menu, the friendships your site make it easier to create – it’s got everything excellent, and it is assisting our son in addition to the family understand that concept is fun, and that is unbelievably mandatory. Thank you for all the pieces!