Walking through a store, you see those small displays near the checkout or in aisles. Ever wonder what the industry calls them? Knowing the lingo helps you plan your own retail strategy.

In retail, PDQ most often stands for "Pretty Darn Quick." It can also mean "Product Displayed Quickly." It refers to a type of retail display, usually made of cardboard, designed for fast setup in stores, often arriving pre-filled with products.

The name tells you a lot about the main benefit. PDQ packaging is all about speed and efficiency on the retail floor. But there is more to it than just the name. Let's explore what makes a PDQ display so common and effective.

What Defines a PDQ Display in Retail?

Still picturing just a simple box? Wondering what makes it a PDQ? It's not just about being quick; it's about specific design features built for the retail environment.

A PDQ is defined by its design for rapid placement and display1 in stores. These units are usually shipped with products already inside, acting as both shipping container and instant display. They are a type of Shelf-Ready (SRP) or Retail-Ready Packaging (RRP).

The core idea behind a PDQ display is to minimize the work2 needed at the retail store level. Think about the time store employees spend unpacking boxes and arranging individual products on shelves. This takes a lot of time and costs money for the retailer. PDQ displays cut down on that labor significantly, sometimes by replacing steps that took minutes with steps that take seconds.

The Design Principle: Speed and Efficiency

The name "Pretty Darn Quick" isn't formal industry jargon, but it perfectly captures the spirit of PDQ. These displays are specifically engineered for speed and ease of handling at every step after leaving the manufacturing facility.

- Integrated Function: A key characteristic is that the PDQ serves a dual purpose. It's robust enough to function as a shipping container during transit from our factory in China to the retail distribution center or even directly to the store. Then, with minimal alteration, it becomes the display unit on the sales floor. This integration eliminates the need for separate shipping cartons and display assembly.

- Pre-Loaded Products: Products are placed into the PDQ display units during the packaging process at the factory or a co-packing facility. They arrive at the store ready to sell. Store staff do not need to unpack individual items from larger boxes.

- Minimal In-Store Effort: The design requires very few steps for store employees. Often, they just need to open a master carton holding several PDQs, lift out a PDQ unit, potentially remove a simple lid or tear a perforated strip, and place the entire unit on the designated shelf or counter. This contrasts sharply with the time-consuming process of breaking down bulk cases, finding shelf space, and arranging products individually.

PDQ as Part of Retail-Ready Packaging (RRP)

PDQ is a specific format within the broader concept of Retail-Ready Packaging (RRP) or Shelf-Ready Packaging (SRP). RRP/SRP is designed to optimize the entire supply chain from production to point of sale.

- The Five "Easys":3 RRP/SRP often follows the principles of the "Five Easys": Easy to Identify (clear labeling in the warehouse), Easy to Open (minimal tools needed in store), Easy to Place (single movement to the shelf), Easy to Shop (products accessible to customers), and Easy to Dispose (simple breakdown for recycling). PDQ excels particularly at "Easy to Place" and "Easy to Shop."

- Supply Chain Optimization: Implementing RRP/SRP, including PDQs, helps retailers manage inventory more effectively, reduces handling damage, and speeds up the flow of goods from the back room to the sales floor.

- Driving Adoption: Because of these operational benefits, major retailers worldwide, especially in North America and Europe, often have specific requirements for SRP/RRP and encourage or even mandate its use for certain product categories. As a manufacturer shipping to these markets, understanding and complying with these varying retailer guidelines is something we handle for our clients. A PDQ that doesn't meet a retailer's exact height or width specifications might be rejected, no matter how well-designed or quickly it sets up.

Material and Durability

While the core principle is quick setup and retail readiness, the physical construction of PDQ displays varies.

- Primary Material: The vast majority of PDQ displays are constructed from corrugated cardboard. This material provides a good balance of strength to hold products and withstand shipping, lightweight characteristics to minimize freight costs, and a surface that is excellent for high-quality printing and branding. Different flute types (like E-flute or B-flute)4 are chosen based on the weight of the product the display needs to hold.

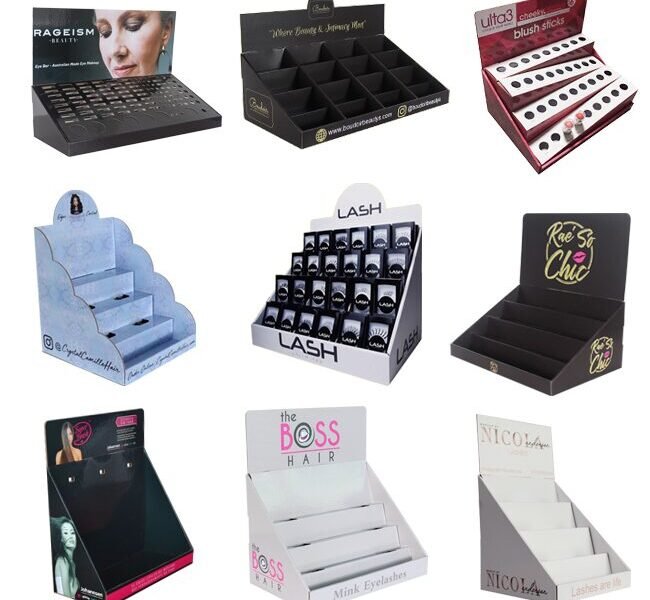

- Design Variations: Structures range from simple open trays to multi-tiered step displays for visibility, or angled gravity-feed designs where products roll forward as units are taken. These structures are achieved through precise die-cutting of the corrugated board.

- Purpose-Driven Durability: Most PDQs are designed for temporary use – typically a few weeks for a promotion or seasonal push. They are durable enough for this intended lifespan on the shelf, but generally not built for long-term, permanent retail display. However, some PDQs, particularly those holding heavier items or intended for longer campaigns, might use thicker board or reinforced elements. Less commonly, PDQ-like structures can be made from more durable plastics or even wood, but these lose the cost and weight advantages of corrugated.

In my experience, the challenge in manufacturing PDQ displays is perfecting the balance – creating a structure using cost-effective corrugated board that protects the product through potentially long international shipping routes (our usual sea freight to North America or Europe) and then performs flawlessly in a busy retail environment, allowing for that "pretty darn quick" placement that retailers love. It requires precise engineering and material selection5 based on the product and the intended supply chain.

Where Do You Typically See PDQ Displays in Stores?

You know those little displays that catch your eye? Wondering where retailers usually put them for maximum impact? Location is everything in retail, and PDQ placement is strategic.

PDQ displays are frequently placed in high-traffic areas throughout a retail store, including checkout counters, aisle endcaps, and main aisles ("Action Alley"). Their placement is strategic to maximize product visibility and encourage impulse purchases.

The strategic placement of PDQ displays is a key factor in their effectiveness for driving sales. Retailers carefully select locations where customer traffic is high and where shoppers are likely to be receptive to seeing products outside of their standard aisle location. This isn't random; it's a deliberate part of store planning and visual merchandising, aiming to intercept customers and influence purchasing decisions at opportune moments.

Prime Real Estate: High-Visibility Zones

The most common spots for PDQ displays are areas with maximum exposure to shoppers walking through the store. These high-traffic zones are premium locations because more eyeballs mean more potential sales.

- Point of Sale (POS) / Checkout Areas: This is arguably the most classic location for smaller, countertop PDQ displays. While customers wait in line to pay, their attention is often available. Items placed here are typically smaller, lower-priced goods or everyday essentials that make for easy, unplanned purchases. Think candy, gum, lip balm, batteries, or small convenience items. The PDQ format is perfect here because it's compact, easy for checkout staff to grab product from, and quick to swap out when stock is low or a promotion changes. The quick setup means staff can easily restock or replace displays even during busy periods.

- Aisle Endcaps (Point of Purchase - POP): Endcaps are the display areas located at either end of a retail aisle. They are highly visible from the main walkways of the store. PDQ displays are frequently used on endcaps to feature promotional items, highlight new product launches, showcase seasonal goods (like holiday items or back-to-school supplies), or present special offers. An endcap display breaks the visual monotony of standard shelving and draws attention from shoppers walking down the main aisles. PDQ endcap displays are often larger than countertop versions, sometimes taking the form of stacked units or full floorstands.

- Main Aisles / "Action Alley": In larger retail formats like supermarkets or big-box stores, the main aisles or central walkways (sometimes called "Action Alley" in the US) experience very high foot traffic. Floorstanding PDQ displays or multiple PDQ units stacked on pallets can be placed in these areas. This placement is typically for promotional items or products the retailer wants to move quickly or gain high visibility for. It's a less common location for very small countertop PDQs, but ideal for larger, standalone displays.

Placement Strategy Based on Product and Goal

The type of product and the marketing goal also influence the specific PDQ type and its location.

- Impulse Items: Best at POS or locations where customers pause. Small countertop PDQs are perfect.

- Promotional Bundles or New Products: Often featured on endcaps or in Action Alley where they can command more space and attention. Larger shelf PDQs or floorstands are suitable.

- Cross-Merchandising: Sometimes PDQ displays are placed within related aisles (e.g., barbecue sauce near chips) to encourage complementary purchases, though endcaps and checkouts are still more common high-traffic spots.

Retailers usually have strict guidelines, known as planograms6, that dictate the exact size, layout, and placement of all displays, including PDQs, within their stores. For a brand, getting your custom packaging into a PDQ format that meets a retailer's specific planogram requirements is essential for securing placement. As a manufacturer, we work with clients to design PDQs that not only look good and protect the product but also comply with the target retailer's sometimes very specific dimension and structural demands. This attention to detail ensures the PDQ arrives ready to occupy its prime retail spot.

Why Are PDQ Displays So Effective for Brands and Retailers?

Just a quick display? Is there more to it? PDQ displays offer significant advantages beyond just saving time. They are powerful tools for driving sales and streamlining operations.

PDQ displays are effective because they increase product visibility significantly, act as a "silent salesperson"7 through branding and graphics, are ideal for driving impulse purchases and promoting seasonal/new items, and simplify stocking for retailers, even though they are often temporary.

The widespread use of PDQ displays in retail isn't just because they are convenient; it's because they deliver tangible results for both the companies selling products and the stores selling them. They function as crucial elements in the point-of-purchase (POP) marketing strategy, influencing consumer behavior right where buying decisions are made.

Powerful Benefits for Brands

For a brand, getting product onto a PDQ display in a prominent retail location is a major win. It's a direct marketing opportunity on the sales floor.

- Cut Through the Clutter: Standard retail shelves are incredibly crowded, with products fighting for attention. A dedicated PDQ display immediately sets your product apart. Its unique structure, size, and placement make it stand out from the rows of standard packaging in the main aisle. This increased visibility is critical for attracting shoppers who might otherwise miss your product.

- Branding and Messaging: The PDQ display is a canvas. You control the graphics, colors, logos, and text printed on it. This allows the display to communicate key brand messages, highlight promotions ("Buy One Get One Free!"), or explain product benefits ("New & Improved Formula!") right at the point of sale. This visually reinforces your brand identity and acts like a dedicated mini-billboard, functioning as a "silent salesperson" that informs and persuades customers.

- Driving Impulse Sales: Placed in strategic, high-traffic areas like checkout counters or endcaps, PDQ displays are perfectly positioned to capture impulse purchases. Products that are appealing, easy to grab, and often lower in price benefit hugely from this placement. The convenience of seeing and grabbing the product without having to search an aisle is a major factor.

- Launchpad for New or Seasonal Products: PDQs are ideal for introducing new items or pushing seasonal offerings (holiday candy, sunscreen in summer, cold remedies in winter). Their temporary nature makes them flexible for short-term campaigns, creating excitement and immediate awareness for timely products.

- Ensured Product Presentation: When products are shipped in a PDQ, the brand controls how they are arranged and displayed. This ensures products are always facing forward, neatly organized, and presented consistently across different store locations, maintaining brand standards and visual appeal.

Clear Advantages for Retailers

Retailers are strong advocates for PDQ displays because they offer significant operational efficiencies and contribute to sales goals.

- Labor Cost Reduction: This is a primary driver. The "Pretty Darn Quick" setup directly translates to less time spent by store staff on unpacking and stocking shelves. This reduces labor costs, a major expense for retailers. Imagine stocking one PDQ unit in 30 seconds versus spending 5 minutes unpacking a traditional case and placing items individually. Over a whole store, the savings add up dramatically.

- Optimized Inventory Flow: PDQs streamline the process from the backroom to the sales floor. They are easy to identify, quick to move, and fast to place, improving the flow of goods and helping to ensure products are available to customers when they want to buy them.

- Effective Use of Prime Space: Retailers can utilize high-value, high-traffic locations like endcaps and checkouts most effectively with PDQ displays. These displays are designed to fit specific retail footprints and maximize sales in these areas, generating revenue that might not occur with standard shelving.

- Reduced Shelf Maintenance: PDQ units keep products contained and organized, reducing the amount of tidying and rearrangement needed on shelves throughout the day.

- Simplified Waste Management: Since most PDQs are corrugated, they are easy for store staff to flatten and add to the recycling stream, simplifying the waste process compared to mixed materials.

While PDQs are often designed for relatively short campaigns (typically 4-12 weeks), their construction is robust enough to endure the handling and stocking process and maintain their appearance on the sales floor for that period. Some PDQs might even be durable enough for longer use depending on the product and retailer requirements. The mutual benefits – increased sales visibility for brands and operational efficiency for retailers – make PDQ displays a standard and effective tool in the retail environment.

How Are PDQ Displays Designed and Produced?

Thinking about creating a custom PDQ for your product? Unsure how a simple piece of cardboard becomes a functional display? The design and manufacturing process is precise, balancing structure and appearance.

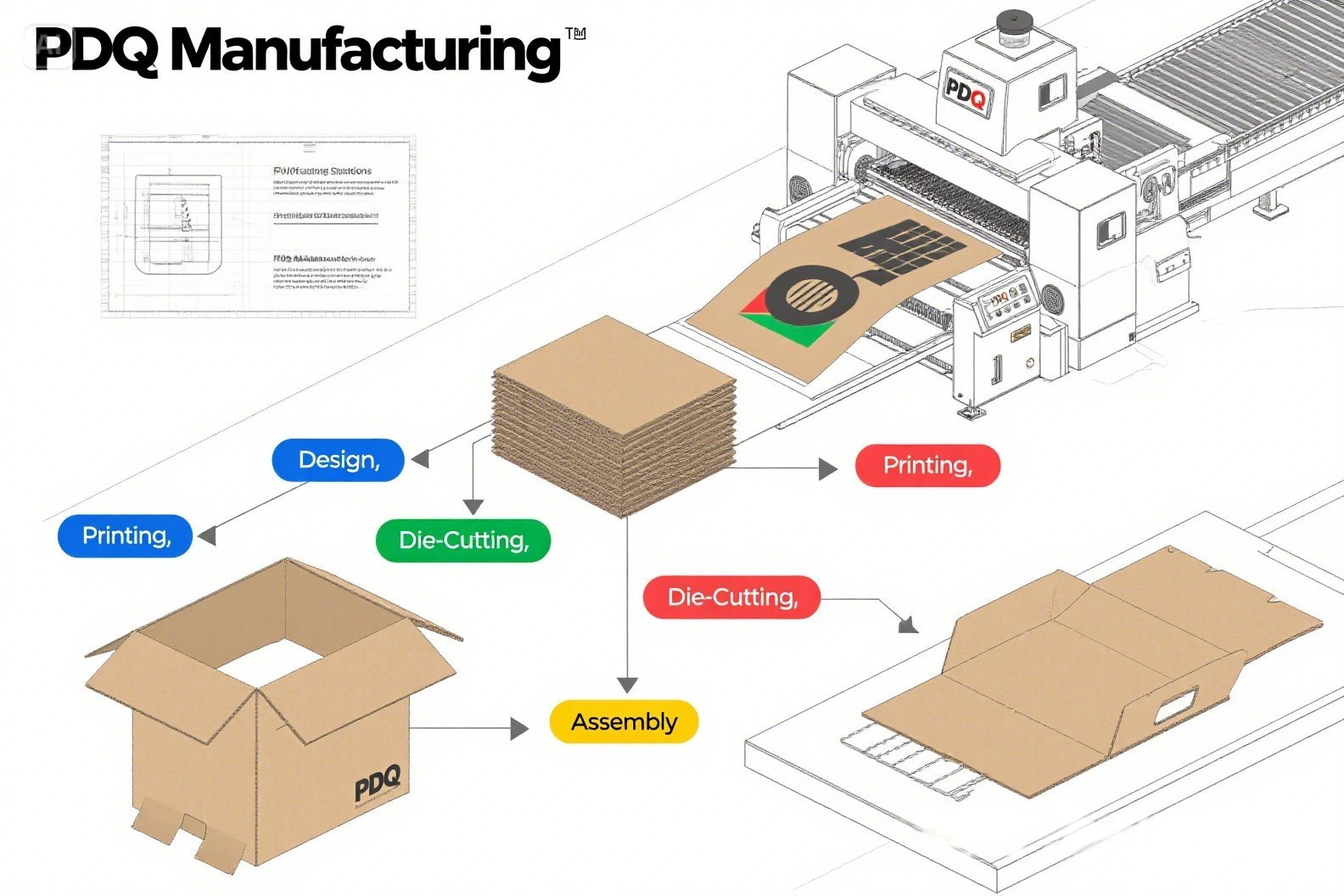

Custom PDQ displays are designed based on product specifications and retailer requirements. They are typically produced from corrugated cardboard using processes like high-quality printing (offset or flexo), precise die-cutting, and efficient folding/gluing, often involving sampling before mass production.

As a packaging manufacturer like Finer-Packaging, the design and production of PDQ displays is a core part of our business. It requires careful attention to both structural engineering and graphic design to create a unit that performs well from our factory floor in China all the way to the retail shelf in North America or Europe. The process involves several key steps8.

The Design Phase: Balancing Form and Function

Design is where the magic starts, but it's grounded in practical requirements.

Gathering Requirements: The first step is understanding the product and its journey. This includes:

- Product Details: Size, weight, shape of the items that will go inside the PDQ. How many items per PDQ?

- Retailer Specifications: Crucially, any guidelines from the target retailer regarding display dimensions (height, width, depth), weight limits, material requirements, and how the unit needs to open or be placed. These specs are non-negotiable if you want placement in a specific store.

- Shipping Method: How will the PDQs be packed for shipping (e.g., in a master carton, directly on a pallet)? How will they travel (sea freight, air freight)? This impacts the required strength and protective features.

- Branding and Marketing: What is the visual design concept? What message needs to be conveyed on the display?

Structural Design: Our structural designers create the physical blueprint of the PDQ using specialized CAD (Computer-Aided Design) software. This involves determining the best shape, how the board will be cut and folded, where the scores (crease lines) and cuts will go, and how it will hold the product securely. They select the appropriate corrugated board flute type (like E, B, or C flute) and board strength based on the product weight and stacking requirements. The goal is a structure that is sturdy, easy to pack, protects the product, and is simple for the retailer to deploy.

Graphic Design: Based on the brand's artwork and marketing message, the graphic design is laid out onto the structural dieline created in the previous step. This artwork needs to be high-resolution, use the correct color modes (CMYK for photos, Pantone for brand spot colors), and include bleed areas.

Production Phase: Bringing the Design to Life

Once the design is finalized and approved (often after sampling), production begins.

- Plate and Die Making: Custom printing plates are made for each color if using offset or flexographic printing. A custom steel rule cutting die is manufactured based on the structural design blueprint. These are one-time costs for the specific design and structure.

- Printing: The graphic design is printed onto large sheets of paper or directly onto the corrugated linerboard.

- Offset Printing: Offers the highest quality for complex graphics and color accuracy. Printed onto a thin sheet which is then laminated onto the corrugated board.

- Flexographic Printing: Often more cost-effective for simpler graphics and larger runs, printed directly onto the corrugated.

- Lamination (If Offset): The printed sheet is precisely glued or mounted onto the corrugated board.

- Die-Cutting: The sheets are fed into a die-cutting machine, where the steel rule die cuts the exact shape of the PDQ (tray, header card, etc.) and creates the necessary scores for folding.

- Folding and Gluing (If Applicable): Some PDQ designs require folding and gluing sections (like side walls) using automated machinery.

- Finishing Touches: Special finishes like gloss or matte lamination, spot UV, or foil stamping are applied in separate steps if specified in the design.

- Quality Control: Throughout the entire process, from incoming materials to printing, cutting, and assembly, quality checks are performed to ensure dimensions, color accuracy, structural integrity, and overall appearance meet specifications. Our ISO 9001:2015 certification guides these processes.

Sampling: Ensuring It's Right

Before the full production run (which meets our MOQ of 500 or 1000+ pieces), sampling is a crucial verification step.

- Digital Samples: Quick and lower cost, produced with digital printing. Good for checking size, structure, and basic layout, but colors are approximate.

- Pre-production Samples (PPS): Made using the actual production methods and materials. This is the best way to see the final color, finishes, and quality before the main order and is highly recommended for approval.

After your approval of the sample, the full production run is scheduled (typically 10-15 business days for us), followed by packing for international shipment. The design and production process is complex but results in a specialized packaging unit designed specifically for retail success.

Conclusion

PDQ, meaning "Pretty Darn Quick" or "Product Displayed Quickly," identifies retail displays made for speed and ease. Strategically placed, they boost visibility and drive sales, offering benefits to both brands and retailers.

Learn the specific design features that make PDQ units fast and easy to place on retail shelves. ↩

Define the broader packaging categories (SRP/RRP) that PDQ belongs to and their retail goals. ↩

Learn the specific five criteria used to evaluate effective RRP/SRP design. ↩

Understand differences in flute types affecting strength and print quality. ↩

Understand how careful design choices ensure packaging success. ↩

Explain what planograms are and how retailers use them. ↩

Understand how packaging design communicates brand messages directly. ↩

Understand the essential inputs (product details, store rules) for starting PDQ design. ↩