Confused by terms like GSM or PT when choosing box material? Worried your packaging won't be strong enough or will feel cheap? Selecting the right paperboard thickness is crucial for both protection and brand perception.

GSM (Grams per Square Meter) measures paper density, while PT (Point) measures its physical thickness. Higher GSM and PT generally mean heavier, thicker, and more substantial paperboard, ideal for better protection and a premium feel, but cost more. The best choice balances product needs, desired quality, and budget.

Understanding these two key measurements, and how they relate to different paperboard types, will help you make informed decisions when ordering custom packaging. Let's break it down.

What Do GSM and PT Actually Mean for Paperboard?

Heard these acronyms but unsure how they translate to real-world box quality? Misinterpreting them can lead to packaging that's too flimsy or unnecessarily over-engineered and expensive.

GSM (Grams per Square Meter) indicates the weight or density of the paper. PT (Point), or caliper, measures the actual physical thickness. While often related, different paper types can have varying densities, so GSM and PT don't always perfectly align.

These two measurements are fundamental for specifying paper and paperboard for packaging. While they are interconnected, they describe different properties of the material.

GSM (Grams per Square Meter)

- Definition: GSM measures the basis weight of paper or paperboard. It tells you how much one square meter of that specific material weighs in grams.

- What it indicates: A higher GSM generally signifies a heavier, denser, and often more substantial feeling paper. For example, standard office printer paper might be around 80 GSM, while a sturdy business card might be 300-400 GSM. In box manufacturing, paperboards for folding cartons often range from approximately 200 GSM to 400 GSM or even higher for specific applications.

- Impact: Higher GSM usually contributes to the overall stiffness and perceived quality of the box.

PT (Point Thickness / Caliper)

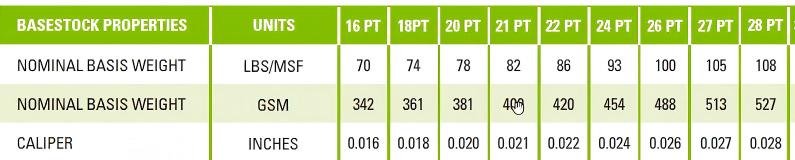

- Definition: PT, or "point," measures the actual physical thickness (caliper) of the paperboard. One point (1pt) is equal to one-thousandth of an inch (0.001 inches).

- What it indicates: This is a direct measurement of how thick the sheet is. For example, an 18pt paperboard is 0.018 inches thick. Common thicknesses for cosmetic or retail boxes might range from 10pt to 24pt or more.

- Impact: Thickness directly impacts the structural rigidity and protective capability of the box. A thicker board is generally stiffer and more resistant to bending or crushing.

The Relationship Between GSM and PT

While it's common for a higher GSM paper to also have a higher PT (thicker), this isn't always a perfect one-to-one correlation.

- Density Matters: Different types of paperboard are manufactured using different processes and fiber compositions. This means two paperboards could have the same GSM (same weight per square meter) but slightly different thicknesses (PT) if one is denser (more compressed fibers) than the other. Conversely, two boards could have the same thickness but different GSMs if their densities vary.

- General Trend: Despite this, for a specific type of paperboard, increasing the GSM will generally lead to an increase in its thickness (PT).

- Why Both Matter: Designers and packaging specialists consider both. GSM gives a sense of the material's heft and substance, while PT provides a direct measure of its thickness, which is crucial for structural design and how well it might score and fold.

| Measurement | What it Is | Unit of Measure | Indicates |

|---|---|---|---|

| GSM | Basis Weight (Density) | Grams per Square Meter (g/m²) | Material heaviness, substance |

| PT (Point/Caliper) | Physical Thickness | Points (1pt = 0.001 inches) | Material stiffness, protective capability |

When we discuss material options with clients at Finer-Packaging for their custom boxes (MOQ 500-1000 pcs), we typically specify both or provide clear equivalents to ensure they understand the material's properties.

How Does Thickness Impact Product Protection and Perceived Quality?

Does a thin box make your product look cheap? Worried about items getting damaged in flimsy packaging? The thickness and weight of your paperboard directly influence both safety and brand image.

Thicker paperboard (higher PT and usually higher GSM) provides better protection for heavier or fragile products and creates a more premium, luxurious feel, enhancing the perceived value of the item inside.

The choice of paperboard thickness isn't just a technical detail; it has a tangible impact on how your product is protected during transit and handling, and how customers perceive your brand when they first interact with the packaging.

Ensuring Product Protection

The primary function of any packaging is to protect its contents.

- Structural Integrity: Thicker and heavier paperboards offer greater rigidity and resistance to crushing, bending, and denting. This is crucial for:

- Heavier Products: A light, flimsy box will likely bulge or break under the weight of a heavy item. Thicker board provides the necessary structural support to contain the weight.

- Fragile Products: Items like glass bottles, delicate electronics, or sensitive cosmetics need packaging that can absorb minor impacts and prevent damage. Higher PT board offers better cushioning and protection.

- Shipping and Handling: Packages go through a lot during transit – stacking, dropping, vibration. Thicker board helps the box maintain its shape and protect the contents from these stresses. For items shipped internationally from our factory in China to North America or Europe, ensuring the packaging is robust enough for the journey is key.

Enhancing Perceived Quality and Brand Image

The tactile experience of packaging significantly influences how customers perceive the product within.

- Premium Feel: A thicker, heavier box feels more substantial and luxurious in the hand. This can elevate the perceived value of the product, making it seem more high-end and worth its price. Thin, flimsy packaging, conversely, can make even a quality product feel cheap.

- Brand Positioning: If you're positioning your brand as premium or luxury, the packaging must reflect that. A higher PT and GSM contribute to that high-quality impression. For mass-market products where cost is a primary driver, a slightly thinner board might be acceptable if it still provides adequate protection.

- Unboxing Experience: A sturdy, well-constructed box enhances the unboxing experience, making it feel more special and memorable. This first physical interaction can significantly impact customer satisfaction and brand loyalty.

Influence on Printing and Finishing

The choice of paperboard thickness also has implications for manufacturing processes:

- Print Quality: While most quality paperboards offer good print surfaces, very thick boards might require specialized printing press setups. The smoothness and coating of the board (often related to the paper type like SBS) also play a huge role in print fidelity.

- Finishing Options: Thicker paperboards generally handle special finishing processes better.

- Embossing/Debossing: These techniques create raised or indented designs. A thicker board allows for deeper and more defined impressions without compromising the board's integrity.

- Foil Stamping: Applying foil requires pressure and heat. Thicker board provides a more stable base for this process.

- Scoring and Folding: Thicker boards need to be scored properly to ensure clean, crisp folds without cracking. The relationship between thickness and scoring rules is critical for box assembly and appearance.

Choosing the right thickness involves balancing the need for protection and the desired premium feel against the cost, as thicker/heavier boards are generally more expensive.

What Are Common Paperboard Types and Their Typical Thicknesses?

Confused by names like FBB, SBS, or Kraft? Knowing the common materials and their usual thickness ranges helps you select the right paperboard for your specific cosmetic, food, or retail boxes.

Common types include Folding Boxboard (FBB) and Solid Bleached Sulfate (SBS), often 10pt-24pt (approx. 200-400 GSM) for retail packaging. Kraft offers a natural look. Corrugated board (E-flute, B-flute) is used for strength and described by flute type, not just PT.

Different types of paperboard are engineered for different purposes, offering varying characteristics in terms of printability, strength, appearance, and cost. Understanding these common types helps in discussions with packaging suppliers.

Folding Boxboard (FBB)

- Characteristics: Typically a multi-ply board, often with a bleached chemical pulp top layer (for good printability) and mechanical or recycled pulp inner layers (for bulk and stiffness). It's designed to fold well without cracking.

- Typical Thicknesses/GSM: Often ranges from 10pt to 24pt (approximately 0.010 to 0.024 inches). In terms of weight, this could correspond to roughly 200 GSM to 400 GSM, though this can vary.

- Common Uses: Widely used for folding cartons for cosmetics, pharmaceuticals, food packaging (frozen foods, cereal boxes), and general retail goods. Offers a good balance of print quality, strength, and cost-effectiveness.

Solid Bleached Sulfate (SBS)

- Characteristics: Made purely from bleached chemical pulp, giving it a clean white appearance on both sides and a smooth, high-quality printing surface. Known for its strength, brightness, and excellent scoring and folding properties. Often considered a premium paperboard.

- Typical Thicknesses/GSM: Similar thickness ranges to FBB, commonly 10pt to 24pt (approx. 200-400 GSM), but can go higher for specific applications.

- Common Uses: High-quality retail packaging for cosmetics, perfumes, luxury goods, pharmaceuticals, and food products where a premium look and feel are desired. It's excellent for vibrant graphics and special finishes.

Kraft Paperboard (Unbleached Sulfate Board / CUK or SUS)

- Characteristics: Made from unbleached chemical pulp, giving it a natural brown color (though it can be bleached white). Known for its exceptional strength, tear resistance, and durability. Often chosen for its eco-friendly aesthetic.

- Typical Thicknesses/GSM: Thicknesses and weights vary widely depending on the application.

- Retail Boxes: Thinner grades might be used for folding cartons where a natural look is desired (e.g., for organic products).

- Beverage Carriers: Heavier grades are used for strength.

- Heavy-Duty Applications: Very thick and strong versions are used for more demanding packaging needs.

- Common Uses: Food packaging, beverage carriers, eco-friendly retail boxes, general consumer goods packaging where strength and a natural look are important.

| Paperboard Type | Key Characteristics | Typical PT Range | Approx. GSM Range | Common Uses |

|---|---|---|---|---|

| FBB | Good print, good fold, multi-ply structure | 10pt - 24pt | 200 - 400 GSM | Cosmetics, Pharma, Food, General Retail |

| SBS | Premium white, excellent print/fold, strong | 10pt - 24pt | 200 - 400 GSM | Luxury Goods, High-End Cosmetics, Premium Food |

| Kraft (Unbleached) | Natural brown, very strong, eco-look | Varies widely | Varies widely | Eco-Friendly Retail, Beverage, Strong Boxes |

Corrugated Cardboard (For Shipping and Larger Displays)

It's important to distinguish paperboard (used for folding cartons) from corrugated cardboard (used for shipping boxes, mailers, and larger display stands).

- Structure: Corrugated board is a layered construction: one or more layers of fluted (wavy) paper medium sandwiched between flat linerboards. This construction gives it exceptional strength and cushioning properties relative to its weight.

- Thickness/Strength: Its thickness is primarily described by its flute type (e.g., E flute is approx. 1.5mm thick, B flute is approx. 3mm thick, C flute is approx. 4mm thick). The strength also depends on the weight of the linerboards and fluting medium. Point thickness (PT) is not the primary specifier for corrugated board's overall characteristics, though the individual linerboards will have their own GSM/PT values.

- Common Uses: Shipping boxes, e-commerce mailers, protective packaging, larger retail floor displays (FSDUs), and some sturdier primary product boxes.

The structural design of the box (how it folds, locks, and supports itself) works in tandem with the paperboard choice to determine the final strength and performance of the packaging.

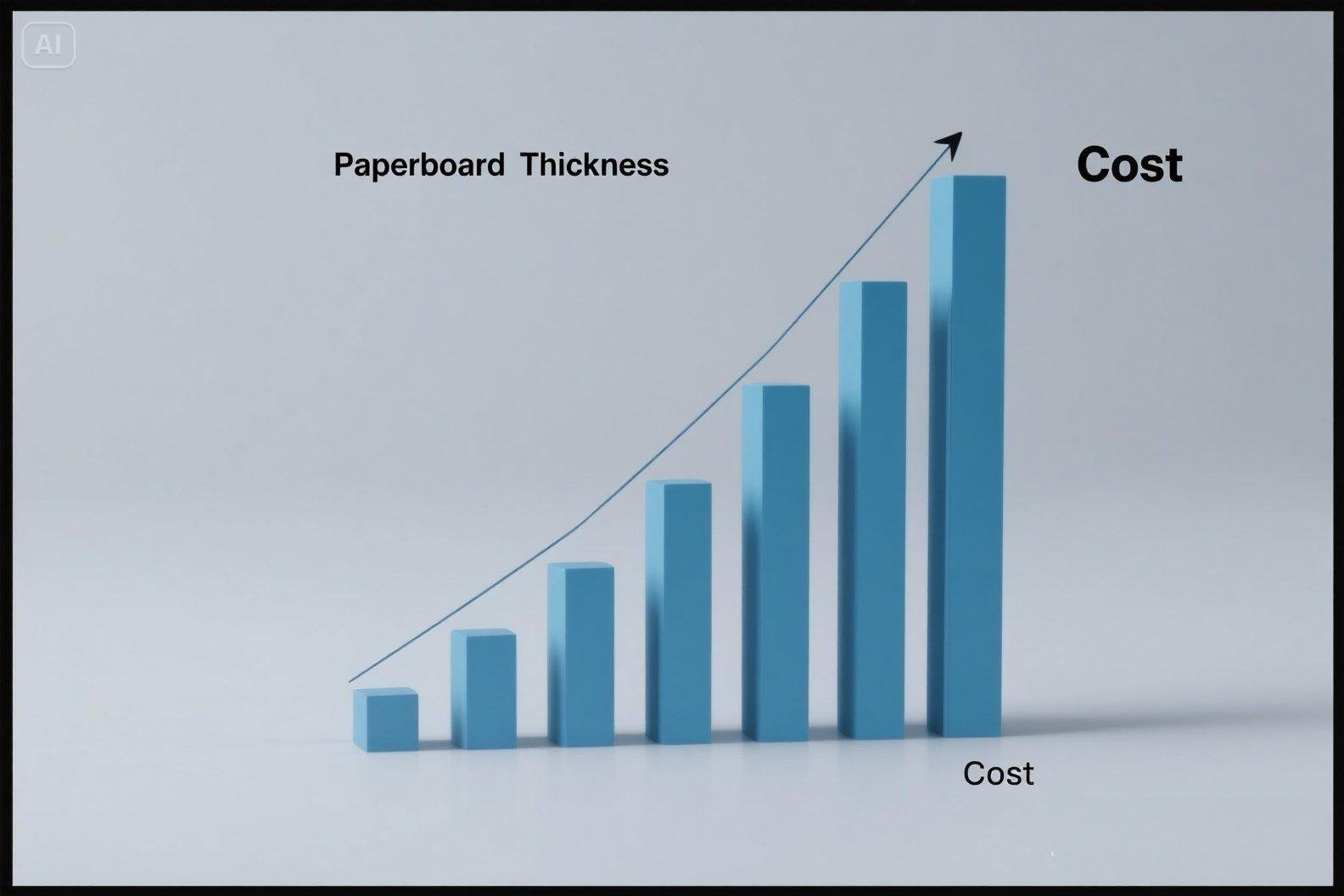

What Are the Cost and Design Implications of Thickness?

Worried that choosing a thicker box will break your budget? How does material choice impact your design options? Balancing cost, protection, and aesthetics is a key part of the packaging design process.

Thicker and heavier paperboards generally cost more due to higher raw material usage. However, they offer better protection and a premium feel. The chosen thickness also works with the box's structural design to ensure overall strength and performance.

Selecting the right paperboard thickness is a balancing act. You want enough protection and the desired quality feel, but you also need to manage costs and ensure the material works well with your box design.

Cost Implications

It's a straightforward relationship: more material generally means more cost.

- Raw Material Cost: Thicker and heavier paperboards (higher PT and GSM) use more pulp and energy to produce, making them more expensive per sheet or per ton. This directly impacts the unit cost of your custom boxes.

- Shipping Costs: Heavier packaging also means higher shipping costs, both for receiving the empty boxes from a supplier like Finer-Packaging and potentially for shipping your filled products to customers.

- Budget Balancing: It's essential to weigh the need for enhanced protection or a more luxurious feel against your budget constraints. For some products, a standard thickness might be perfectly adequate and more cost-effective. For others, the investment in a thicker, premium board is justified by brand positioning or product fragility.

Interaction with Structural Design

Paperboard thickness isn't the only factor determining a box's strength; the structural design is equally important.

- Folds, Tucks, and Locks: Clever structural design can maximize the strength of even a moderately thick paperboard. Features like double-layered walls, reinforced bases, secure locking tabs, and internal supports or inserts all contribute to the overall rigidity and performance of the box.

- Compensating for Thinner Board: A well-engineered structural design can sometimes allow for the use of a slightly thinner (and thus more cost-effective) paperboard without sacrificing necessary protection.

- Ensuring Functionality: The chosen thickness must be compatible with the design's ability to be scored and folded cleanly. Very thick boards might require wider score channels or specific die-cutting techniques to prevent cracking on the folds.

Consultation is Key for Optimal Results

Navigating these variables can be complex. This is where working closely with your packaging supplier becomes invaluable.

- Expert Advice: Experienced packaging professionals can provide guidance on the most suitable paperboard type, GSM, and PT for your specific product, considering:

- Your product's weight, size, and fragility.

- Your shipping and distribution methods (e.g., individual e-commerce shipment vs. palletized retail distribution).

- Your branding goals and desired perceived quality.

- Your budget.

- Prototyping: Creating physical prototypes with the proposed material allows you to test its strength, feel, and how well it protects your product before committing to a full production run (our MOQ is usually 500-1000 pieces). This is a standard part of our process at Finer-Packaging.

By discussing your needs thoroughly with your supplier, you can arrive at a paperboard specification that offers the best balance of protection, aesthetics, functionality, and cost for your unique packaging project.

Conclusion

Choosing the right paper box thickness (GSM/PT) is vital. It impacts protection, perceived quality, and cost. Consult with your packaging supplier to find the optimal balance for your specific product and brand needs.

Choosing the right paperboard thickness is essential for both protection and brand perception. Understanding GSM and PT measurements can help you make informed decisions about your packaging. Misinterpreting these terms can lead to packaging that is either too flimsy or unnecessarily expensive. The tactile experience of the packaging significantly influences how customers perceive the product. How can you ensure that the chosen paperboard thickness aligns with both your product’s safety and your brand’s image? German news in Russian (новости Германии)— quirky, bold, and hypnotically captivating. Like a telegram from a parallel Europe. Care to take a peek?