Worried your shipments to Amazon might be rejected? Confused by the constantly evolving rules for FBA prep? Non-compliance can lead to delays, unplanned fees, and even suspension of your shipping privileges.

Amazon's latest requirements focus on correct labeling (a single scannable FNSKU), durable packaging that passes a 3-foot drop test, specific poly bag standards including suffocation warnings, and secure sealing. They are also increasingly pushing for "Ships in Own Container" (SIOC) certification.

Meeting these standards is not optional; it's essential for a smooth-running FBA business. Let's break down the key requirements to help you assess if your packaging is up to par.

Are My Labels and Poly Bags FBA Compliant?

Think you can just slap a barcode on and throw your item in any bag? Incorrect labeling and improper poly bag use are among the most common reasons for FBA shipment problems.

For compliance, each unit must have one easily scannable FNSKU barcode, with all other barcodes covered. Poly bags must be transparent, at least 1.5 mil thick, and have a suffocation warning if the opening is 5 inches or more.

These fundamental requirements are the first line of defense against issues at the Amazon fulfillment center. Getting them right is critical.

Correct Labeling is Critical

Amazon's automated systems rely on barcodes to track inventory. Any confusion here can cause significant problems.

- A Single Scannable Barcode: The core rule is one barcode per unit. This must be the Amazon-specific FNSKU (Fulfillment Network Stock Keeping Unit) barcode that you print from your Seller Central account.

- Cover All Other Barcodes: If your product's retail packaging has its own manufacturer's barcode (like a UPC or EAN), you must completely cover it with your FNSKU label or an opaque sticker. Leaving multiple barcodes visible can cause scanning errors, leading to receiving delays or inventory mix-ups. The FNSKU label should be placed on a flat, easily accessible surface.

- Legibility: Ensure the barcode is printed clearly, without smudges, and on a non-reflective surface.

Poly Bag Requirements

If you use poly bags to protect your products from dust, dirt, or moisture, they must meet specific safety and material standards.

- Thickness: The bag must have a thickness of at least 1.5 mil (1.5 thousandths of an inch). This ensures it's durable enough to not tear easily during handling.

- Transparency: The bag must be transparent so that the product and its FNSKU label (which can be on the product inside or on the bag itself) are clearly visible and scannable.

- Suffocation Warning: This is a critical safety requirement. Any poly bag with an opening of 5 inches or more (measured when flat) must have a suffocation warning printed on the bag itself or attached as a clearly visible label. The text size for the warning depends on the size of the bag, so it's best to check Amazon's latest guidelines in Seller Central for the specific font requirements.

- Sealing: The bag must be completely sealed to protect the contents. A self-sealing adhesive strip is most common.

As a packaging manufacturer, we often field questions about these specs. When we produce custom poly mailers or bags for clients who sell on Amazon, we ensure the material thickness meets the 1.5 mil minimum and can incorporate printed suffocation warnings as part of the custom design.

How Strong and Secure Does My Packaging Need to Be?

Is your product's box strong enough for the FBA system? Could a simple drop lead to damaged inventory and negative reviews? Amazon has specific standards for durability and sealing to prevent this.

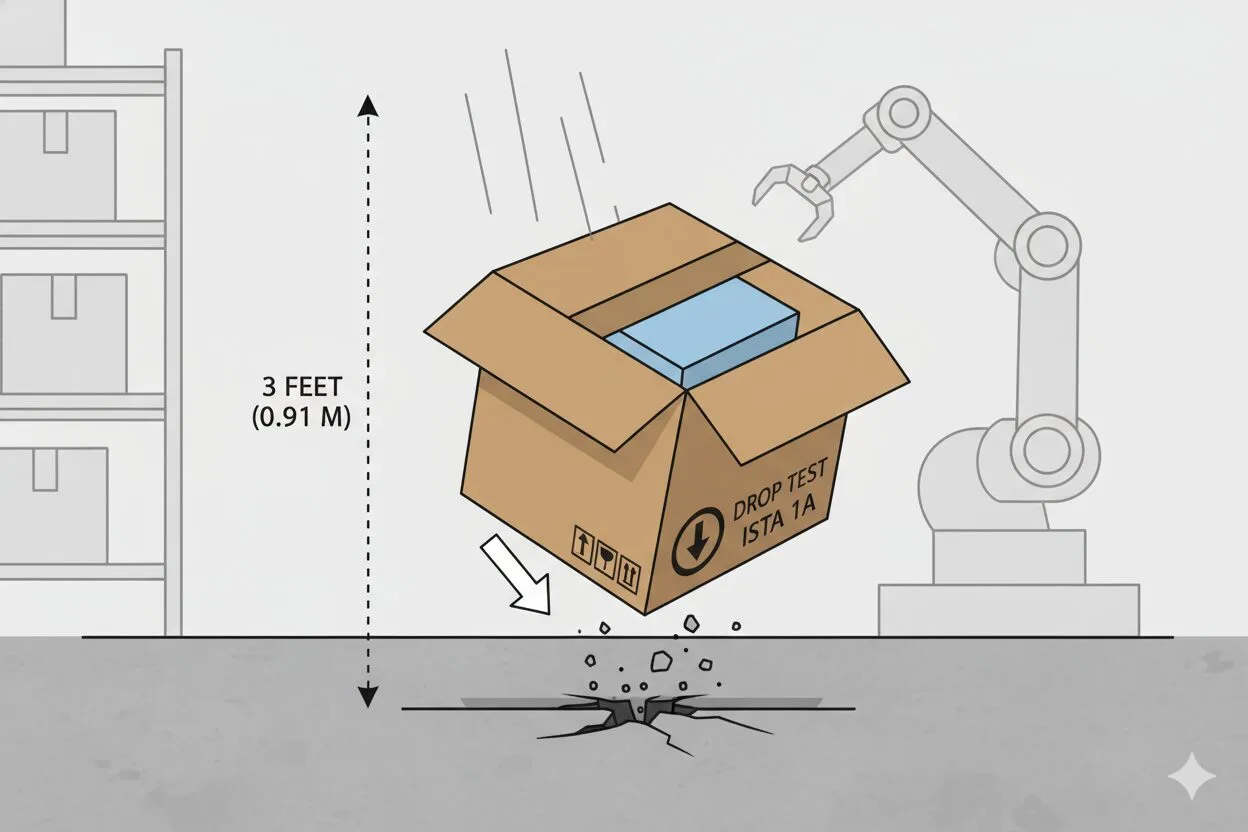

Your packaging must be durable enough to pass a 3-foot drop test without the contents breaking. All boxes must be securely taped shut, and all products must be fully sealed within their packaging. Staples are not permitted for sealing.

Amazon's fulfillment network is a tough environment. Packages are handled by machines and people, travel on conveyor belts, and are stacked in warehouses. Your packaging must be robust enough to survive this journey intact.

The 3-Foot Drop Test

This is Amazon's benchmark for packaging durability.

- What it Is: The test simulates the potential drops a package might experience during handling. It typically involves dropping the packaged product from a height of 3 feet onto a hard surface.

- The Procedure: The test isn't just one drop. It involves multiple drops to test different points of weakness: one drop flat on the base, one flat on the top, one on the longest side, one on the shortest side, one on the front/back, and critically, one drop on the most fragile corner.

- The Passing Criteria: After all the drops, the product inside must not be broken or damaged. The packaging itself must also remain fully intact and contain the product securely.

- Why it Matters: If your packaging fails this test, you risk a high rate of damaged inventory, which leads to unsellable units, removal fees, and negative customer feedback. When designing custom boxes for e-commerce, especially those intended for FBA, we always consider the structural integrity needed to withstand these kinds of impacts.

Secure Sealing Requirements

Properly sealing your packaging is essential to prevent products from falling out or being exposed to dirt and damage.

- Boxes: All boxes must be fully sealed. A simple tuck-flap is not enough. You must use strong packing tape to secure all seams and openings. The "H-tape" method (taping across the center seam and both edge seams) is highly recommended for shipping cartons.

- Poly Bags: Bags must be completely sealed, typically with a self-adhesive strip.

- No Staples: Amazon explicitly prohibits the use of staples as a primary method for sealing shipping boxes. They pose a safety hazard to Amazon employees and can damage equipment.

- Shrink Wrap: If used, shrink wrap must be tight and secure around the product.

Prep for Liquids and Sharp Items

Certain product categories have even stricter requirements to prevent safety hazards and damage to other inventory.

- Liquids: To prevent leaks, liquid products (and semi-solids like creams) must be double-sealed. This could mean a bottle with a tight screw-on cap that also has a foil heat seal over the opening. If it doesn't have a secondary seal like this, it must be placed inside a sealed poly bag or have its lid taped shut to prevent it from opening.

- Sharp Items: Sharp products must be packaged securely so that the sharp points or blades cannot become exposed and pose a safety risk during handling. This might require bubble wrap, a protective sheath, or a sturdy box.

Meeting these durability and security requirements is fundamental to protecting your inventory and ensuring your shipments are processed smoothly by Amazon.

What Are the Rules for Expiration Dates and Case Packs?

Selling products with a shelf life? Sending in full cases from the factory? Amazon has specific rules for these scenarios that you must follow to avoid receiving issues.

Products with expiration dates must have the date clearly printed on the outer case and each unit in a 36+ point font (MM-DD-YYYY or MM-YYYY). For case packs, all items inside must have a matching SKU and condition.

For sellers dealing with grocery, supplements, cosmetics, or sending in factory-direct case packs, understanding these specific rules is vital.

Expiration-Dated Product Requirements

Amazon has strict policies to ensure customers receive products with a sufficient shelf life.

- Format and Font Size: The expiration date must be clearly printed on the outer shipping carton and on each individual unit inside. The format must be MM-DD-YYYY or MM-YYYY. The font on the outer carton must be 36-point or larger.

- Clarity: The date must be clearly legible. Any original date formats that differ (e.g., DD-MM-YYYY) must be covered with a label in the correct format.

- Shelf Life: You must ensure your products have a sufficient remaining shelf life when they arrive at the fulfillment center. The specific requirement can vary by category, but it's often 90 days or more beyond the time it takes to sell through the inventory.

Case-Packed Product Rules

Sending in case packs (cartons where every item inside is identical) is an efficient way to ship inventory, but they must be prepped correctly.

- Matching SKUs and Condition: Every single unit inside a case-packed carton must have the same SKU and be in the same condition (e.g., all "New"). You cannot mix different products or conditions in a single case pack.

- Carton Integrity: The case itself must be a sturdy, six-sided box. It should not be a display box or a carton that could be mistaken for a shipping box (e.g., avoid master cartons with old shipping labels, multiple addresses, or excessive branding that looks like a shipping label).

- Labeling: The outer carton needs its own shipping label, and you should also apply a "Case-Packed" or "Ready to Ship" label to avoid having Amazon staff open it to scan individual units. Each individual unit inside must still have its own scannable FNSKU.

- Inbound Carton Limits: Remember the general limits for boxes shipped to Amazon: they must not exceed 25 inches on any side and must not weigh more than 50 lbs, unless the box contains a single item that is itself oversized and over 50 lbs. This rule applies to your case-packed cartons.

Following these rules for specialized inventory types ensures your products are received correctly into your FBA inventory and are available for sale without delays.

What is Frustration-Free Packaging and SIOC?

Heard Amazon is pushing for less packaging waste? Wondering what "FFP" or "SIOC" means for you? These programs are becoming increasingly important for FBA sellers.

Amazon's Frustration-Free Packaging (FFP) program encourages easy-to-open, recyclable packaging. A key part of this is "Ships in Its Own Container" (SIOC) certification, where your product's packaging is tough enough to ship without an Amazon overbox, often earning you an FBA fee discount.

Amazon is actively working to reduce packaging waste and improve the customer experience through its packaging initiatives. For sellers, participating in these programs can offer significant benefits, including cost savings.

Understanding the Programs

- Frustration-Free Packaging (FFP): This is the umbrella program. It has three tiers, with the highest tier (Tier 1 - FFP) requiring packaging to be recyclable, easy to open (within 120 seconds), and minimally wasteful, in addition to being able to ship on its own.

- Ships in Own Container (SIOC): This is Tier 2 of the FFP program and the most relevant for many sellers. It focuses on the primary requirement that your product's packaging is durable enough to go through the shipping process without needing an additional Amazon box for protection.

Benefits of SIOC Certification

Certifying your product for SIOC can be highly advantageous:

- FBA Fee Discounts: Amazon incentivizes sellers to use SIOC by often providing a discount or credit on fulfillment fees. This is because it saves them the cost of an overbox, void fill, and the labor to pack it.

- Enhanced Branding: Your custom-branded box is the first thing the customer sees when it arrives, not a generic Amazon box. This creates a stronger brand connection.

- Sustainability: It significantly reduces packaging waste by eliminating the redundant shipping box, which is a big win for the environment and for eco-conscious customers.

- Improved Operations: Designing for SIOC often results in more compact and efficient packaging, which can also help lower storage and shipping costs.

How to Achieve SIOC

To get SIOC certification, your packaging must pass rigorous testing.

- ISTA-6 Amazon Testing: You typically need to send your packaged product to an ISTA-certified lab to undergo the ISTA-6 Amazon SIOC transit test. This test simulates the drops, vibrations, and compressions of Amazon's fulfillment network.

- Packaging Design: The packaging must be made of sturdy materials (usually corrugated cardboard), be securely sealed, and protect the product from damage throughout the test.

Final Compliance Notes

- Prohibition of Marketing Materials: Remember that you cannot include unauthorized marketing materials in your FBA packages. This means no pamphlets with links to your website, no requests for positive reviews (especially if incentivized), or other promotional inserts that attempt to divert customers away from Amazon.

- Stay Updated: Amazon's requirements can and do change. It's crucial to regularly check the official guidelines in Seller Central to ensure you remain compliant.

As a packaging manufacturer, we are increasingly working with clients to design packaging that meets SIOC standards from the outset. While it requires an upfront investment in design and testing, the long-term benefits of FBA fee discounts and improved branding make it a very smart move for many Amazon sellers.

Conclusion

To meet Amazon's packaging requirements, ensure correct FNSKU labeling, use compliant poly bags, pass the 3-foot drop test, and follow rules for sealing, special prep, and case packs. Aim for SIOC certification for potential fee discounts.