Struggling to make your products stand out in crowded store aisles? Need a cost-effective way to launch promotions? Custom cardboard floor displays can grab attention without breaking the bank.

Custom cardboard floor displays, also known as FSDUs (Free Standing Display Units), are versatile marketing tools. You can order them tailored to your exact needs from manufacturers or specialized suppliers, balancing design, practicality, and cost effectively.

Ordering these displays might seem complicated, but it's straightforward when you know what factors to consider. Let's walk through the process of getting effective custom cardboard floor displays for your brand.

How Customizable Are Cardboard Floor Displays?

Think cardboard limits your creative options? Worried you can't match your unique brand style? Cardboard is surprisingly versatile, allowing for highly specific and eye-catching designs.

Cardboard floor displays are incredibly customizable. You can tailor the size, shape, structure, print graphics, and branding elements completely to match your specific products and marketing goals, ensuring a unique presentation.

One of the biggest strengths of cardboard as a display material is its adaptability. Forget generic stands; custom cardboard displays allow you to create something truly unique that embodies your brand and perfectly showcases your product. As a manufacturer, we at Finer-Packaging thrive on this customization potential.

Tailoring Size, Shape, and Structure

The physical form of your display can be fully customized.

- Dimensions: You dictate the exact height, width, and depth needed. This ensures the display fits retailer space requirements and holds your product volume efficiently.

- Shape: Go beyond simple rectangular towers. Die-cutting1 allows for curved edges, unique silhouettes that might mimic your product or logo, or attention-grabbing asymmetrical designs.

- Structure: Design features like multiple tiers, individual product compartments, shelves angled for gravity feed, integrated brochure holders, or hooks for hanging items can all be incorporated. The structure can be fully tailored to how your product is best presented and accessed by shoppers.

Considering Product Needs

Effective customization considers the product itself.

- Weight Support: The product's weight is crucial. Heavier items require stronger corrugated board2 (e.g., B-flute or even double-wall constructions) and reinforced structural design (internal supports, load-bearing shelves) to ensure the display remains stable and durable in a busy retail environment. Lightweight items allow for more delicate structures or lighter board grades like E-flute. We always discuss product weight early in the design process to ensure adequate support.

- Size & Fit: The display's compartments or shelves should be sized appropriately for the product dimensions, holding items securely but allowing easy removal by customers.

High-Impact Graphics and Branding

Cardboard provides an excellent surface for printing, turning your display into a powerful branding tool.

- Full Graphic Coverage: You can print high-resolution graphics across the entire visible surface of the display – sides, back panel (header), shelves, and base.

- Printing Options: High-quality printing methods3 like offset lithography (often laminated onto the board for the best finish), flexography (good for simpler graphics/larger runs), or digital printing (ideal for shorter runs or prototypes) allow for vibrant colors and detailed imagery. This ensures your branding looks sharp and attracts customer attention.

- Brand Consistency: Use your exact brand colors (Pantone matching4 is possible), logos, fonts, and campaign messaging to create a cohesive brand experience right on the sales floor.

Design Support

Creating an effective display involves both structural and graphic design expertise.

- Supplier Assistance: Many manufacturers, including Finer-Packaging, offer design support. We can provide structural design services based on your product and needs, supply dieline templates for your graphic designer, or sometimes offer graphic design assistance. Prototyping services are also valuable for testing the design before a full production run.

The combination of structural flexibility and high-quality printing means cardboard floor displays can be fully customized to create a unique, effective, and on-brand presence in any retail setting. My team often works closely with clients to translate their marketing goals into a functional and eye-catching display design.

What Makes Cardboard Floor Displays Practical for Retail?

Are bulky, heavy displays causing logistical nightmares? Worried about difficult assembly or disposal? Cardboard displays offer practical advantages that simplify life for both brands and retailers.

Cardboard displays are highly practical due to their lightweight nature, ease of transport and assembly (often flat-packed), and simple recyclability. Their cost-effectiveness also makes them ideal for short-term promotions.

While visual appeal and customization are important, the practical aspects of handling, setting up, and disposing of displays are crucial in the real world of retail. Cardboard excels in these areas, making it a favorite for many promotional activities.

Cost-Effectiveness for Campaigns

Compared to permanent fixtures, cardboard is significantly more budget-friendly.

- Lower Material & Production Costs: As discussed before, cardboard itself and the processes to shape and print it are less expensive than working with plastics, metal, or wood.

- Ideal for Short-Term Use: This cost advantage makes cardboard perfect for temporary displays tied to specific promotions, seasons, or product launches. You can create high impact for a limited time without a massive investment, allowing for frequent refreshes and keeping your retail presence dynamic.

Lightweight and Easy Handling

The physical properties of corrugated board make logistics much simpler.

- Reduced Shipping Costs: Being lightweight directly translates to lower transportation costs compared to heavier materials – a significant factor when shipping bulk orders internationally from manufacturers like us in China.

- Easy Transport within Stores: Retail staff can easily carry flat-packed displays or move assembled displays around the store for optimal placement without needing heavy lifting equipment.

- Repositioning Flexibility: Need to move the display to a different aisle or endcap? Lightweight cardboard makes this a simple task, allowing retailers to adapt layouts easily.

Simple Assembly

Many cardboard floor displays are designed with ease of assembly in mind.

- Flat-Packed Delivery:5 Displays often ship flat to save space and reduce shipping costs.

- Tool-Free Assembly: Designs frequently utilize interlocking tabs, slots, and pre-creased folds, allowing store staff to assemble the display quickly and easily, often without needing any tools like screwdrivers or wrenches. Clear instruction sheets are usually included. This simplicity increases the likelihood that the display will be set up correctly and used effectively.

Eco-Friendly Choice

Sustainability is a growing concern for consumers and brands. Cardboard offers strong environmental credentials.

- Recyclability: Cardboard is widely recycled. At the end of a campaign, displays can be easily broken down and placed in standard cardboard recycling streams, simplifying disposal for retailers.

- Recycled Content: Many cardboard options are available with high percentages of recycled fiber content.

- Renewable Resource: Paper fibers come from trees, a renewable resource, especially when sourced from responsibly managed forests (like FSC-certified sources).

- Appealing to Consumers: Choosing eco-friendly display materials can resonate positively with environmentally conscious shoppers, enhancing brand image. We find many clients specifically request recycled or recyclable options.

These practical benefits – cost savings, easy handling, simple setup, and sustainability – make cardboard floor displays a highly efficient and responsible choice for driving sales in retail environments.

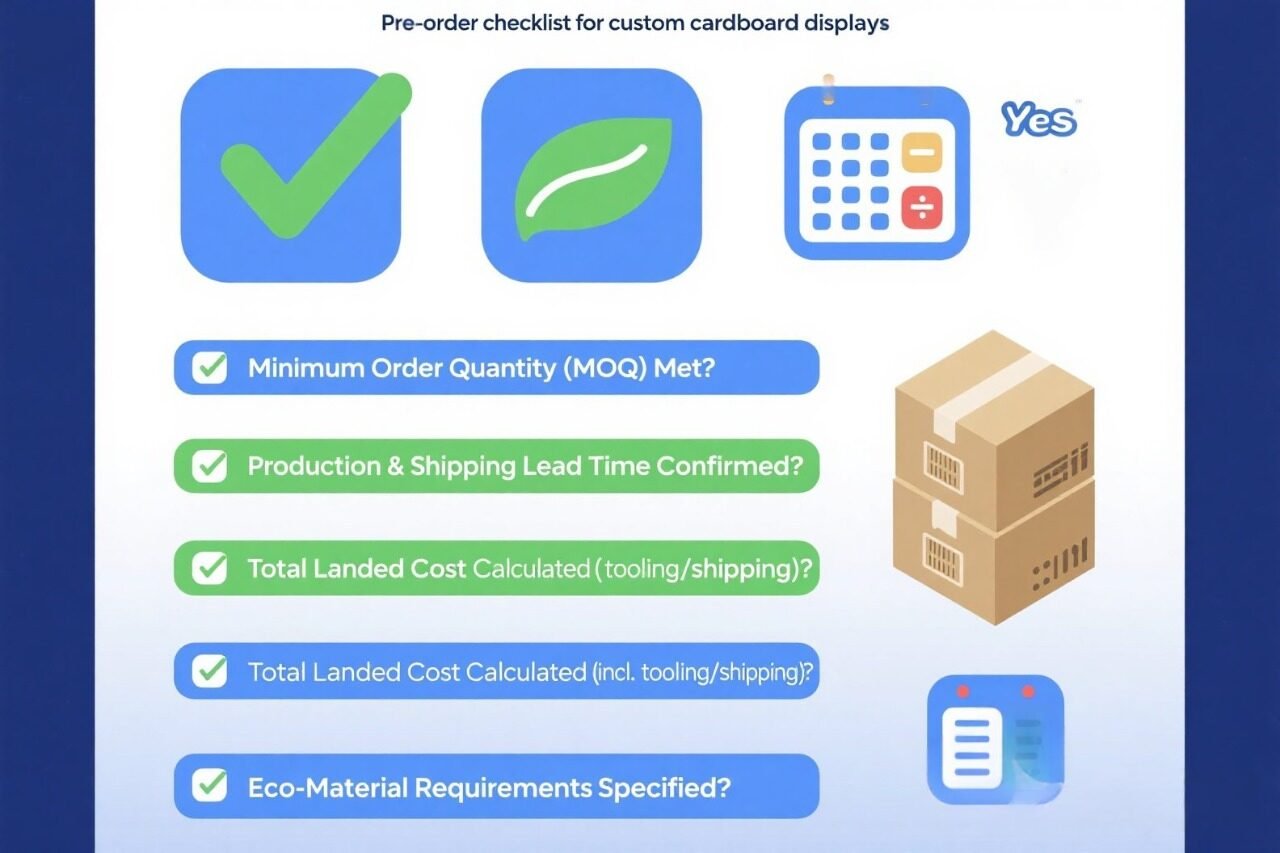

What Do You Need to Know Before Ordering Cardboard Displays?

Ready to order, but unsure about quantities, timelines, or total costs? Overlooking key details can lead to budget issues or missed deadlines. Planning ahead ensures a smooth ordering process.

Before ordering, clarify minimum order quantities (MOQs), understand production and shipping lead times, evaluate the total landed cost including potential tooling and shipping fees, and specify any eco-friendly material requirements.

Ordering custom displays involves more than just approving a design. Understanding the logistical and financial details upfront is essential for a successful project, especially when dealing with manufacturers for bulk orders.

Minimum Order Quantities (MOQs)

Manufacturers typically have MOQs because setting up production machinery (printing presses, die-cutters) involves fixed costs and time. Running very small batches is inefficient and drives the per-unit cost up significantly.

- Varying MOQs: The MOQ can vary depending on the supplier and the complexity of the display. Online platforms catering to small businesses might offer lower MOQs (perhaps 50-100) often using digital printing. Direct manufacturers like Finer-Packaging, using offset or flexo printing for higher volumes, usually have higher MOQs (e.g., 100-500 units might be typical for floor displays, though this varies – always ask).

- Price Breaks: Always inquire about price breaks at different quantities. Often, ordering slightly more than the absolute minimum can result in a substantially lower cost per display due to economies of scale.

Production and Delivery Lead Times

Timing is crucial, especially for promotional campaigns.

- Production Time: This is the time needed to manufacture the displays after you approve the final design/sample. Factors influencing this include design complexity, order quantity, printing method, and the manufacturer's current workload. A typical range might be 2-4 weeks, but always confirm with your specific supplier. Our standard production time at Finer-Packaging is usually 10-15 business days.

- Shipping Time: This is additional time, especially important when sourcing internationally. Sea freight from China to North America or Europe can take 3-6 weeks. Air freight is much faster but significantly more expensive. Factor this transit time into your overall project timeline.

- Total Lead Time: Ensure the combined production and shipping time allows the displays to arrive well before your campaign launch date.

Evaluating Total Cost

The price per display unit is just one part of the total investment.

- Manufacturing Cost: The base price per unit, heavily influenced by quantity, size, materials, printing, and finishes.

- Tooling Fees:6 Ask if there are separate one-time charges for custom cutting dies or printing plates. Some suppliers might waive these for very large orders, but they are often itemized separately.

- Design/Prototyping Fees: Costs associated with design assistance or creating physical prototypes/samples.

- Shipping Costs: Get accurate quotes for shipping from the factory to your destination. Understand the shipping terms (Incoterms like FOB, EXW, CIF, DDP) to know what's included.

- Import Duties/Taxes: If importing, research and budget for customs duties, tariffs (like Section 301 tariffs for US imports from China), and taxes (like VAT in Europe). These are paid by the importer in the destination country.

- Landed Cost: Sum all these costs to get the true "landed cost" per display delivered to your door. This is essential for accurate budgeting and comparing quotes from different suppliers (domestic vs. international).

| Cost Component | Included in Unit Price? | Description | Notes |

|---|---|---|---|

| Manufacturing | Yes | Base cost per display | Varies with specs & quantity |

| Tooling (Die/Plates) | Sometimes (clarify) | One-time cost for custom tools | Often separate; reorders usually don't incur |

| Samples/Prototypes | Usually Separate | Cost to create physical samples for approval | Highly recommended for quality assurance |

| Shipping/Freight | Usually Separate | Transport from factory to destination | Significant cost, depends on mode/distance/weight |

| Duties & Taxes | No (Buyer Pays) | Import taxes levied by destination country govt. | Crucial to research for international orders |

Specify Eco-Friendly Options

If sustainability is important, clearly communicate this requirement.

- Recycled Content: Ask for options using post-consumer recycled paper fibers.

- FSC Certification: Request materials sourced from FSC-certified, responsibly managed forests.

- Inks/Adhesives: Inquire about vegetable-based inks or eco-friendly adhesives if needed. Most suppliers now offer various eco-friendly material options.

Clarifying these points before placing your order ensures transparency, helps you manage your budget effectively, and aligns the final product with your expectations and timeline.

Conclusion

Custom cardboard floor displays are a smart choice: cost-effective, highly customizable, easy to handle, eco-friendly, and great for grabbing attention. Careful planning ensures you order displays that effectively boost your brand presence.

Discover precision cutting techniques for brand differentiation ↩

Review certified load test reports to prevent structural failure ↩

Compare printing methods to optimize budgets for small/large orders ↩

Ensure brand color consistency across global shipments ↩

Maximize container space utilization for cost efficiency ↩

Negotiate waived fees for 1000+ unit orders ↩

Good!!!

Thank you!