Custom Gift Boxes Wholesale with Your Logo

Elevate your brand with premium packaging solutions tailored to showcase your identity. Our wholesale custom gift boxes feature three iconic structures designed for diverse applications and luxury appeal:

Magnetic Closure Gift Boxes

Crafted with precision-engineered magnetic alignment (±0.3mm tolerance) and FSC-certified greyboard, these boxes ensure 10,000+ durability cycles. Ideal for high-end cosmetics or watches, they support metallic foil stamping, UV coating (20-25μm), and velvet-lined interiors for tactile sophistication.

Drawer-Style Packaging

Featuring telescoping mechanisms with silicone-lubricated tracks (0.5mm tolerance), these boxes combine functionality with eco-consciousness. Options include PLA-coated pulp inserts, PVC windows for product visibility, and reinforced compression strength (15kg load capacity). Perfect for jewelry or artisanal chocolates.

Heaven-and-Earth Lid Boxes

With 5mm reinforced overlaps and water-resistant coatings (72hr protection), these boxes excel in premium liquor or tea packaging. Customizable with laser-cut windows, gradient foil effects, and embossed logos (1.2mm relief depth), they offer 40% enhanced stacking strength for retail displays.

Key Branding Advantages:

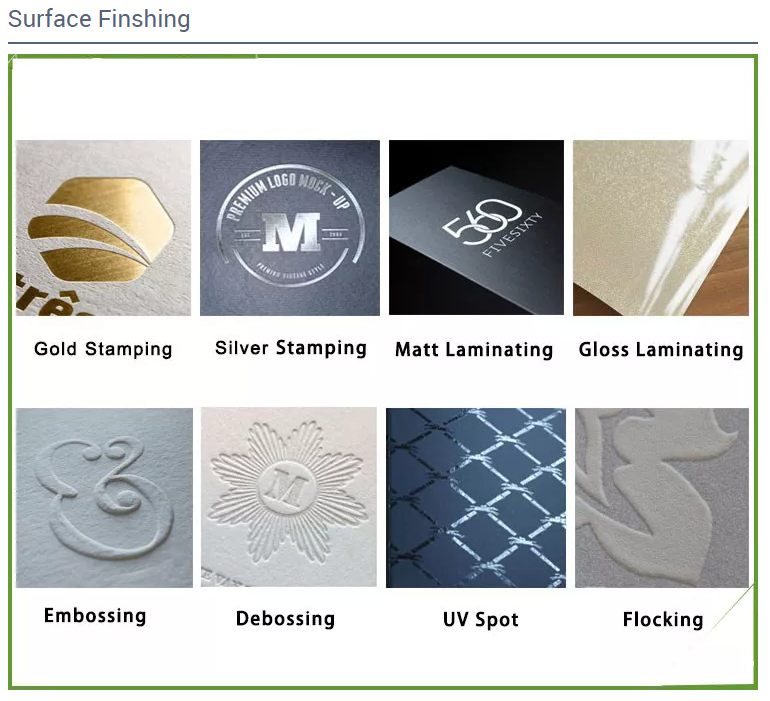

Logo Integration: 20+ finishing techniques including debossing, silk printing, and Pantone-matched CMYK offset printing.

Eco-Compliance: FSC/ISO-certified materials with 85% humidity resistance and recyclable kraft options.

Flexible MOQs: Starting at 500 units for magnetic boxes, 1,000 units for drawer styles, with 15-day rapid production cycles.

From concept to assembly, we provide 3D prototyping and 3-stage QC inspections to ensure your logo becomes synonymous with unboxing excellence. Whether for corporate gifting or luxury retail, these structural designs merge brand identity with functional artistry.

Low MOQ

Order as few as 500 custom gift boxes on your initial wholesale order.

Freely Customizable

Display your brand’s story with a fully customized gift box

Low Cost

Always get a competitive price for your gift boxes

How to Customize the Gift Box?

Customizing a gift box involves a streamlined 5-step process that balances creativity and technical precision:

Step 1: Conceptualization

Design Brief: Share your vision, including box dimensions, structural type (magnetic closure/drawer/heaven-and-earth), and branding goals (e.g., luxury, eco-friendly).

Material Selection: Choose from FSC-certified greyboard (2.5mm for rigidity), linen-textured paper, or biodegradable kraft. For interiors, opt for velvet (2mm thickness) or recyclable EVA foam.

Step 2: Digital Mockup

Use design tools like Adobe Illustrator to finalize artwork placement, ensuring logos align with structural features (e.g., centered on magnetic closure lids or drawer fronts).

Confirm Pantone color codes for metallic foils (gold/silver) or gradient effects.

Step 3: Prototyping

Request a physical sample to test:

Magnetic Boxes: Verify magnet alignment (±0.3mm tolerance) and closure smoothness.

Drawer Boxes: Test sliding mechanism resistance (max. 5N pull force) and insert stability.

Lid-Base Boxes: Check overlap depth (3-5mm) and collar reinforcement.

Step 4: Production

Printing: Offset printing for CMYK designs (170LPI resolution) or hot stamping for logos.

Finishing: Apply UV coating (20-25μm) for scratch resistance or soft-touch lamination.

Assembly: Automated die-cutting for precision edges and food-grade glue application.

Step 5: Quality Assurance

Conduct 3-stage inspections: material thickness (±0.1mm tolerance), color accuracy (ΔE≤3.0), and functional tests (e.g., 1.2m drop tests for ISTA 3A compliance).

Pro Tips:

Cost-Saving: Opt for standard sizes to avoid custom tooling fees.

Sustainability: Add QR codes linking to recycling instructions or brand sustainability stories.

Partner with manufacturers offering end-to-end services, from 3D renderings to global logistics, to streamline the process and ensure your custom boxes reflect your brand’s essence. 🎁✨

Questions You May Be Concerned About

What Printing Methods Are Available for Custom Boxes?

Printing transforms a plain box into a branded package. Different printing techniques offer varying levels of quality, cost, and customization.

The most common printing methods for custom boxes are flexographic printing, digital printing, and lithographic printing. Each method has advantages depending on budget, order size, and design complexity.

Types of Printing Methods

1. Flexographic Printing (Flexo)

- Best for high-volume production.

- Cost-effective but limited to simple designs.

- Uses rubber printing plates.

2. Digital Printing

- Ideal for short runs and complex designs.

- High-quality, full-color printing.

- No setup costs, but higher per-unit price.

3. Lithographic Printing (Offset)

- Best for premium packaging with high-resolution graphics.

- Requires printing plates, making it costly for small runs.

- Commonly used for luxury brands.

For most businesses, digital printing is the best choice for small-to-medium orders, while flexo is preferred for large quantities.

How to Choose the Right Box Size?

Selecting the right box size reduces shipping costs and ensures product safety.

A well-fitted box prevents damage and enhances the unboxing experience.

Measure your product dimensions accurately and choose a box that provides just enough room for cushioning without excess space. Custom-sized boxes reduce material waste and shipping costs.

Steps to Determine the Right Box Size

- Measure Product Dimensions – Length, width, and height.

- Add Cushioning Space – Leave 1-2 inches for protective padding.

- Choose the Box Style – Regular slotted container (RSC) or mailer box.

- Optimize for Shipping Efficiency – Minimize weight and volume to reduce shipping costs.

Custom-sized boxes not only look professional but also improve logistics efficiency.

What Special Finishes and Features Can Be Added?

Special finishes and features enhance the appearance and functionality of your shipping box. They create a memorable unboxing experience for customers.

Common finishes include matte/glossy coatings, embossing, foil stamping, and UV printing. Additional features like inserts and magnetic closures enhance premium packaging.

Popular Finishes for Custom Boxes

| Finish Type | Effect | Best For |

|---|---|---|

| Matte Coating | Soft, non-reflective look | Minimalist brands |

| Glossy Coating | Shiny, vibrant appearance | Bold, colorful packaging |

| Spot UV | Glossy highlights on specific areas | Luxury branding |

| Embossing/Debossing | Raised or recessed text/logo | Premium packaging |

| Foil Stamping | Metallic or holographic effect | High-end, gift packaging |

If your business targets high-end consumers, adding embossing, foil stamping, or a magnetic closure can create a premium feel.

How to Balance Cost and Customization?

Customization can be expensive, but there are ways to optimize costs without sacrificing quality.

To balance cost and customization, choose cost-effective materials, limit color printing, order in bulk, and use simple designs. Digital printing and eco-friendly kraft boxes offer affordable customization.

Cost-Saving Tips for Custom Packaging

- Order in Bulk – Larger orders reduce per-unit cost.

- Use Minimalist Designs – Simple branding can be just as impactful.

- Choose Kraft Material – Affordable and eco-friendly.

- Opt for Digital Printing – Avoids setup costs of traditional printing.

By focusing on essential design elements and strategic ordering, businesses can get custom packaging at reasonable prices.

Conclusion

Customizing a shipping box involves choosing the right material, size, printing method, and finishes while managing costs effectively. Well-designed packaging strengthens brand identity, improves customer experience, and optimizes shipping efficiency. Investing in custom shipping boxes is a smart strategy for businesses looking to enhance their packaging and branding.

How We Work: From Concept to Delivery

01 Consultation & Planning

"We start by understanding your needs and crafting a tailored packaging strategy."02 Design & Develop

"Our team creates innovative designs that align with your brand and product requirements."03 Sample Approval

"We deliver high-quality samples for your review, ensuring every detail meets your expectations."04 Production

"With precision and care, we bring your packaging to life, backed by rigorous quality checks."05 Delivery

"After production, your packages will undergo quality assurance and be dispatched to your preferred location."06 After-Sales Support

"Our commitment doesn’t end at delivery—we’re here to support you every step of the way."

Why Choose Finer Packaging?

Unlock Exceptional Benefits for Your Business

At Finer Packaging, we are dedicated to putting your business’s success first. Whether you’re using our mailers for shipping, branding, or marketing, we ensure a seamless and phenomenal experience from start to finish.

With over 15 years of experience, Finer Packaging has partnered with some of the biggest names in international retail to manage their mailer inventory. Our commitment to excellence has driven us to perfect our packaging materials, ensuring the highest quality and reliability for your business.

What Makes Finer Packaging the Best Choice?

Exclusive Dieline Design

Stand out with custom, professionally designed mailers

Low MOQ (From 500pcs)

Affordable startup with minimum order quantity

7-10 Days Fast Production

Industry-leading turnaround speed

Competitive Pricing

Premium quality at factory-direct prices

We go above and beyond to deliver packaging solutions that align with your business goals. Trust us to provide the expertise, quality, and support you need to elevate your brand and operations.