Struggling with expensive, inflexible displays? Products getting lost on crowded shelves? Cardboard offers a versatile, cost-effective way to grab attention and showcase your items effectively.

Cardboard displays are often best because they are highly cost-effective, incredibly versatile for custom designs, lightweight for easy handling, eco-friendly, and excellent for high-impact printing. This combination makes them ideal for many retail applications.

These benefits sound great on paper, but they translate into real advantages on the shop floor. Let's look closer at why cardboard consistently stands out compared to other materials in key areas like cost, design freedom, practicality, and environmental impact.

How Does Cardboard Compare on Cost and Speed?

Budget constraints limiting your marketing impact? Need displays fast for a time-sensitive promotion? Expensive materials and long production lead times can easily derail campaigns before they even start.

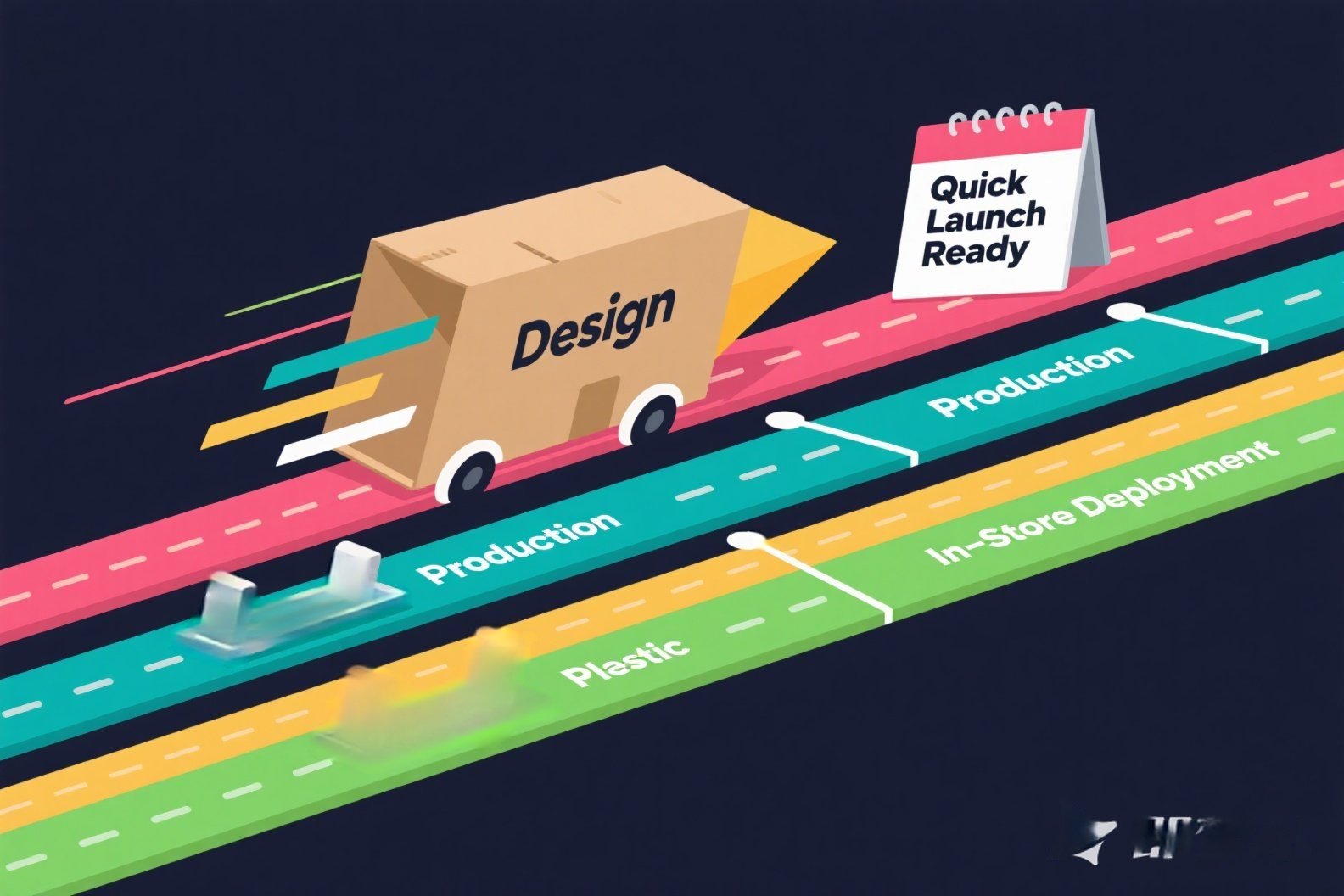

Cardboard is significantly more cost-effective than materials like plastic, metal, or wood. Its production turnaround is also generally faster, enabling quick deployment for promotions or new product launches.

When planning retail displays, budget and timeline are almost always critical factors. This is where cardboard truly shines, offering significant advantages over more permanent or rigid materials.

Unbeatable Cost-Effectiveness

The primary reason many brands choose cardboard displays is their affordability.

- Lower Material Costs: Corrugated cardboard1 or paperboard is inherently less expensive as a raw material compared to acrylic, PVC, ABS plastic, sheet metal, wire, or solid wood.

- Lower Tooling Costs: Creating custom shapes in cardboard primarily involves designing and producing a steel rule cutting die. While this has a cost, it's generally much less expensive than creating injection molds for plastic, complex jigs for metalwork, or intricate routing setups for wood.

- Ideal for Temporary Use: Because they are cost-effective, cardboard displays are perfectly suited for temporary promotions, seasonal campaigns, or product launches where the display only needs to last a few weeks or months. Investing heavily in a metal or plastic stand for a short-term campaign often doesn't provide a good return on investment. Cardboard allows brands to implement impactful displays without breaking the bank, making frequent updates feasible.

Here's a rough comparison of relative costs for a similar sized custom display:

| Material | Typical Relative Cost | Primary Cost Drivers |

|---|---|---|

| Cardboard | $1-$5 | Material Volume, Print Complexity, Quantity |

| Plastic (Acrylic/PVC) | $5 - $10 | Material Cost, Mold Tooling (if molded) |

| Metal (Wire/Sheet) | $10 - $100 | Material Cost, Fabrication Labor, Welding |

| Wood | $20 - $200 | Material Cost (type of wood), Labor, Finishing |

(Note: Actual costs vary greatly based on design complexity, quantity, and specific materials.)

Faster Production Turnaround

In the fast-paced retail world, speed matters. Cardboard displays generally offer quicker production lead times compared to other materials .

- Streamlined Processes: Manufacturing cardboard displays involves relatively straightforward, high-speed processes like printing (offset, flexo, digital), laminating (if needed), die-cutting, and sometimes folding/gluing. These processes are well-established and optimized for efficiency.

- Faster Tooling:2 Creating printing plates and cutting dies is typically faster than creating complex molds or fabrication setups.

- Rapid Deployment: This quick turnaround allows brands to react swiftly to market opportunities, launch promotions quickly, and get new products onto the sales floor faster. Waiting weeks or months for a metal or plastic display might mean missing a key sales window. At Finer-Packaging, our standard production time for custom paper boxes and displays is typically 10-15 business days after sample approval, enabling this marketing agility.

The combination of lower cost and faster production makes cardboard an incredibly practical choice for dynamic retail environments where budgets need to stretch and speed is often essential.

Can Cardboard Displays Truly Be Customized and Eye-Catching?

Feel limited by generic, standard display options? Need your brand's personality to pop off the shelf? Bland, uninspired displays simply won't capture the attention of today's busy shoppers.

Absolutely. Cardboard offers exceptional versatility in custom shapes, sizes, and structures. Its excellent print surface allows for vibrant, high-resolution graphics, making displays highly visible and engaging brand communicators.

Dismissing cardboard as just 'plain brown boxes' is a huge mistake. Modern design and manufacturing techniques allow for incredible creativity, turning simple cardboard into powerful, eye-catching sales tools.

Unmatched Customization and Versatility

Cardboard is like a blank canvas for structural designers. Its ability to be precisely cut and folded allows for an enormous range of custom shapes and structures3, far beyond simple shelving.

- Structural Freedom: Designers can create:

- Countertop Displays (PDQs/CDUs): Compact units for checkouts or shelves.

- Floor Stands (FSDUs): Larger, freestanding displays for aisles or endcaps.

- Dump Bins: Open-top bins for loose or impulse items.

- Tiered/Stepped Displays: Multiple levels for showcasing various products or sizes.

- Pallet Displays: Large displays shipped directly on a pallet for high-volume goods.

- Unique Shapes: Die-cutting allows for displays shaped like products, logos, or thematic elements, making them instantly recognizable and memorable.

- Tailored to the Product: Displays can be designed with custom compartments, shelves, hooks, or inserts to perfectly hold and present specific products, whether it's cosmetics, snacks, electronics, or brochures. This ensures products look organized and appealing.

Superior Printability for Maximum Brand Impact

Cardboard's surface is ideal for high-quality printing, transforming the display into a powerful communication tool.

- Printing Methods: It readily accepts various printing techniques:

- Offset Lithography: Often used for the highest quality graphics, especially when printed on a top sheet that's then laminated to the corrugated board. Delivers sharp images and excellent color reproduction.

- Flexography: Cost-effective for simpler graphics and larger runs, printing directly onto the board liner.

- Digital Printing: Increasingly used for shorter runs or prototypes, offering good quality and fast setup.

- Vibrant Colors & Detail: Whether using CMYK for photographic images or specific Pantone (PMS) colors for precise brand matching, cardboard allows for vibrant, rich colors and detailed graphics that capture attention.

- Brand Messaging: This high print fidelity means logos look sharp, product images look appealing, and promotional text is clear and readable. The display effectively becomes a "silent salesperson," communicating value and encouraging purchase.

Grabbing Attention in Store

The combination of unique structures and high-impact graphics makes cardboard displays highly effective at enhancing product visibility and attracting customer attention. When strategically placed in high-traffic areas4, a well-designed cardboard display can:

- Interrupt the shopper's journey and draw their eye.

- Clearly communicate the product offering and brand identity.

- Make the product seem appealing and easy to purchase.

- Stand out from the visual noise of standard shelving.

Compared to some plastics which might have limitations in print quality or shape complexity without expensive molding, or metal/wood which are harder to print on directly with high detail, cardboard offers a superior combination of structural versatility and printability for creating truly unique and eye-catching displays.

Are Cardboard Displays Practical and Eco-Friendly?

Worried about displays being difficult to ship, assemble, or move? Concerned about the environmental footprint of your marketing materials? Practicality and sustainability are increasingly important considerations for brands and consumers alike.

Cardboard displays are highly practical: lightweight for easy transport and repositioning, often designed for simple, tool-free assembly. They are also a leading eco-friendly choice, being widely recyclable and often made from recycled content.

Beyond cost and aesthetics, the day-to-day usability and end-of-life considerations of displays matter. Here, cardboard again presents significant advantages.

Lightweight, Portable, and Easy to Assemble

The physical nature of corrugated cardboard makes these displays exceptionally user-friendly.

- Lightweight: Compared to wood, metal, or thick acrylic displays, cardboard stands are significantly lighter. This translates directly into lower shipping costs, both inbound from the manufacturer (like Finer-Packaging in China) and potentially outbound if pre-packed displays are sent to multiple retail locations.

- Easy Transport & Repositioning: Store staff can easily move lightweight cardboard displays within the store to optimize placement or adapt to changing layouts without needing special equipment or excessive effort.

- Simple Assembly: Many cardboard displays are designed to ship flat to save space and cost. Assembly in-store is often intuitive, involving simple folds and locking tabs – frequently requiring no tools or specialized skills. This contrasts with potentially complex assembly for metal or wood fixtures. This ease of setup is crucial for ensuring displays are actually used correctly in busy retail environments.

A Leading Sustainable Choice

In an era of increasing environmental awareness, the eco-credentials of packaging and displays are under scrutiny. Cardboard is a strong performer in this area.

- High Recyclability: Corrugated cardboard and paperboard are among the most widely recycled materials globally. Most curbside and commercial recycling programs readily accept cardboard. This makes end-of-life disposal simple and environmentally responsible.

- Recycled Content: Cardboard itself is often made with a high percentage of recycled paper fibers, reducing the need for virgin materials. We prioritize using eco-friendly materials that meet standards like FSC5.

- Renewable Resource: Virgin paper fibers come from wood pulp, a renewable resource when sourced from responsibly managed forests (like those certified by FSC - Forest Stewardship Council).

- Contrast with Alternatives: While some plastics are recyclable, the infrastructure is less consistent, and mixed materials can complicate recycling. Metal and wood are durable but have a higher initial resource and energy footprint in manufacturing and are heavier to transport. Cardboard offers a compelling balance of performance and lower environmental impact, particularly for temporary displays.

Effective Organization and Access

Well-designed cardboard displays also contribute to a better shopping experience.

- Product Organization: Custom compartments or tiers keep products neat, organized, and prevent them from becoming jumbled, which improves the overall shelf appearance.

- Easy Shopping: Displays are usually designed with open fronts or easy-access structures, making it simple for customers to see the products clearly and pick them up without difficulty.

The combination of practical handling benefits and strong environmental credentials makes cardboard a responsible and efficient choice for modern retail display needs.

Conclusion

Cardboard displays offer an often unbeatable mix of affordability, high customization potential, print quality, ease of use, and sustainability, making them a top choice for effective product showcasing in many retail situations.

Explore the uses of corrugated cardboard in packaging and displays. ↩

See how long it takes to create tools for cardboard vs plastic. ↩

Explore the wide variety of structural designs possible with cardboard. ↩

See common locations in stores where displays are most effective. ↩

Learn about FSC standards for responsible forestry used in paper. ↩